Product description:

The split machine for leather is designed to cut leather materials into layers according to specific thickness to meet different process requirements. Such machines are usually equipped with precise control systems to ensure accuracy and repeatability of the cutting process. Its structure is sturdy, easy to operate, and can adapt to long-term industrial production needs.

Product advantages:

1. Accuracy: The use of advanced CNC technology ensures the consistency and accuracy of cutting thickness and improves the quality of finished products.

2. High efficiency: The 1800mm wide working surface enables a large amount of material to be cut at a time, greatly improving production efficiency.

3. Easy to maintain: The design takes into account the quick replacement of wearing parts, reducing downtime and maintenance costs.

4. Versatility: The cutting parameters can be adjusted according to the characteristics of different leathers, and it is suitable for splitting operations of a variety of leather materials.

5. Safety: Necessary safety protection devices are provided to ensure the safety of operators.

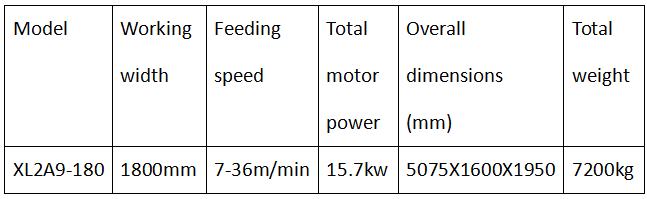

Product parameters:

Product application:

Splitting machines for leather are widely used in the production process of leather products such as shoes, clothing, bags, and household items. It can split the leather into the required thin slices according to the design requirements, and these thin slices can be used to make various leather products. For example, in the shoemaking industry, the leather processed by the splitting machine can be used to make shoe uppers; in the clothing industry, it can be used as fabric for making leather clothing. In addition, the splitting machine can also be used for leather reprocessing, such as re-splitting waste leather to recycle the high-quality fibers.

Mobile:+86-15919644519

E-mail: packy@tannerymachine.com

Skype: gmpacky

Whatsapp: +86-15919644519