Product description:

Water squeezing and stretching machine is an important equipment in the leather production process. It is mainly used to squeeze and stretch the wet cow leather before vacuum drying and flattening drying. This step helps remove moisture from the leather while improving its texture and softness through stretching, improving the quality of the final product.

Product advantages:

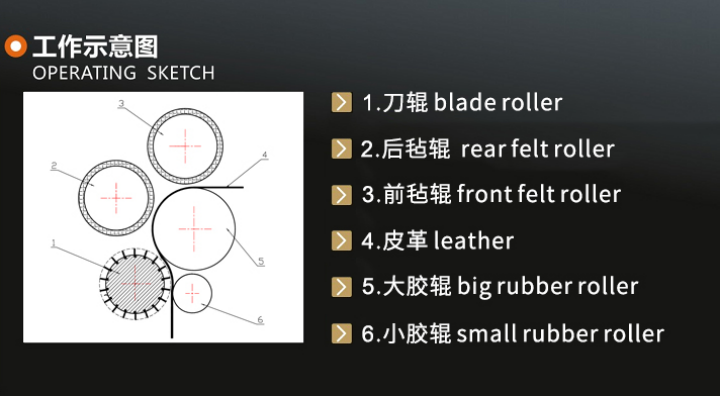

1. Structural composition: Leather water squeezing machine consists of two felt rollers, two rubber rollers and one knife roller. This structure can provide more uniform and effective pressure during the water squeezing and stretching process.

2. Water squeezing effect: Since each piece of leather will be squeezed out twice by the front and rear felt rollers in one working cycle, this ensures that the leather is squeezed dryer and improves the efficiency of the subsequent drying process.

3. Stretching strength: Each roller is equipped with an independent power system, so that the stretching strength can be adjusted according to the characteristics of different leathers, thereby improving the leather yield rate of the leather (that is, the conversion rate from raw leather to finished leather).

4. Reduce damage: The knife roller and small rubber roller adopt a hydraulic swing method. This design can reduce damage caused by direct contact with the roller while the leather stretches, thereby protecting the integrity of the leather surface.

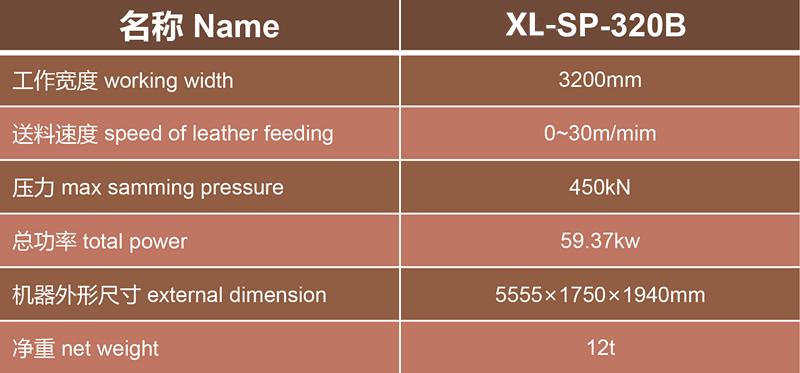

Product parameters:

Product application:

1. Water squeezing function

One of the basic functions of the Water squeezing and stretching machine is to remove excess moisture from the wet cow leather through physical squeezing. This is crucial for the subsequent drying process, as excess moisture affects drying efficiency and may lead to a loss of leather quality. Through the water squeezing and stretching machine, the moisture content of wet cow leather can be reduced to a certain proportion to meet the needs of subsequent processing.

2. Stretch function

This machine is not just a simple water squeezing device, it also has a stretching function. By properly stretching the leather, the texture and softness of the leather can be improved, improving the quality and appearance of the final product. The stretched leather is flatter, reducing wrinkles and improving the overall aesthetics and use value of the leather.

3. Improve production efficiency

The equipment improves production efficiency through automation and optimized design. The appropriate working speed can be adjusted according to the needs of different leather materials, thereby optimizing the production process.

4. Improve leather quality

The machine helps improve the quality of the leather through water squeezing and stretching processes. Squeezing reduces the moisture in the leather, while stretching improves the leather's texture, and the two combined can significantly improve the quality of the leather.

Mobile:+86-15919644519

E-mail: packy@tannerymachine.com

Skype: gmpacky

Whatsapp: +86-15919644519